Navigate

Welcome to ART CNC

CNC Plasma, CNC Routers, CNC Laser & Plasma Beamlines

We’ve been designing & building industrial CNC machines for the global market for over 25 years. So whether your business is large or small, we can walk you through the decision making process and give you accurate advice. Our goal is to ensure you get the machine that is right for your business. Call us now and talk to the company that actually designs, builds and programs the machines they sell!

ART CNC Machines by Type

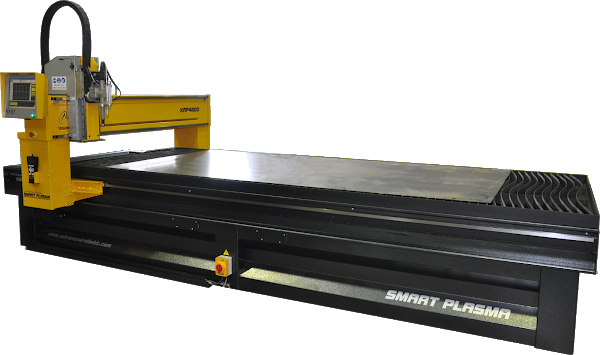

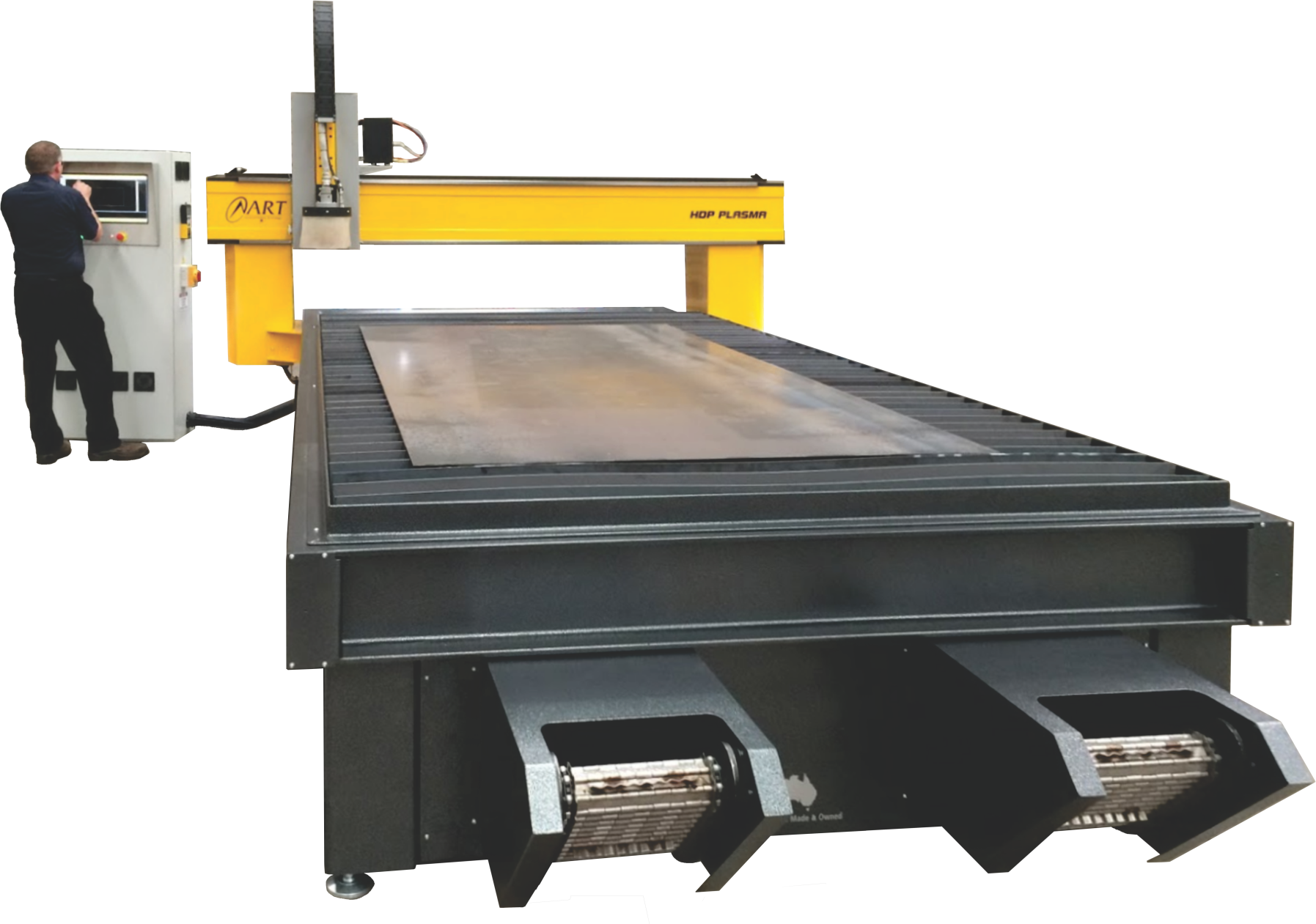

Affordable solutions for all types of metal cutting using state of the art plasma systems from Hypertherm

Advanced CNC Routing machines for efficient processing of Aluminium, Plastic, Timber, Composites and even Steel!

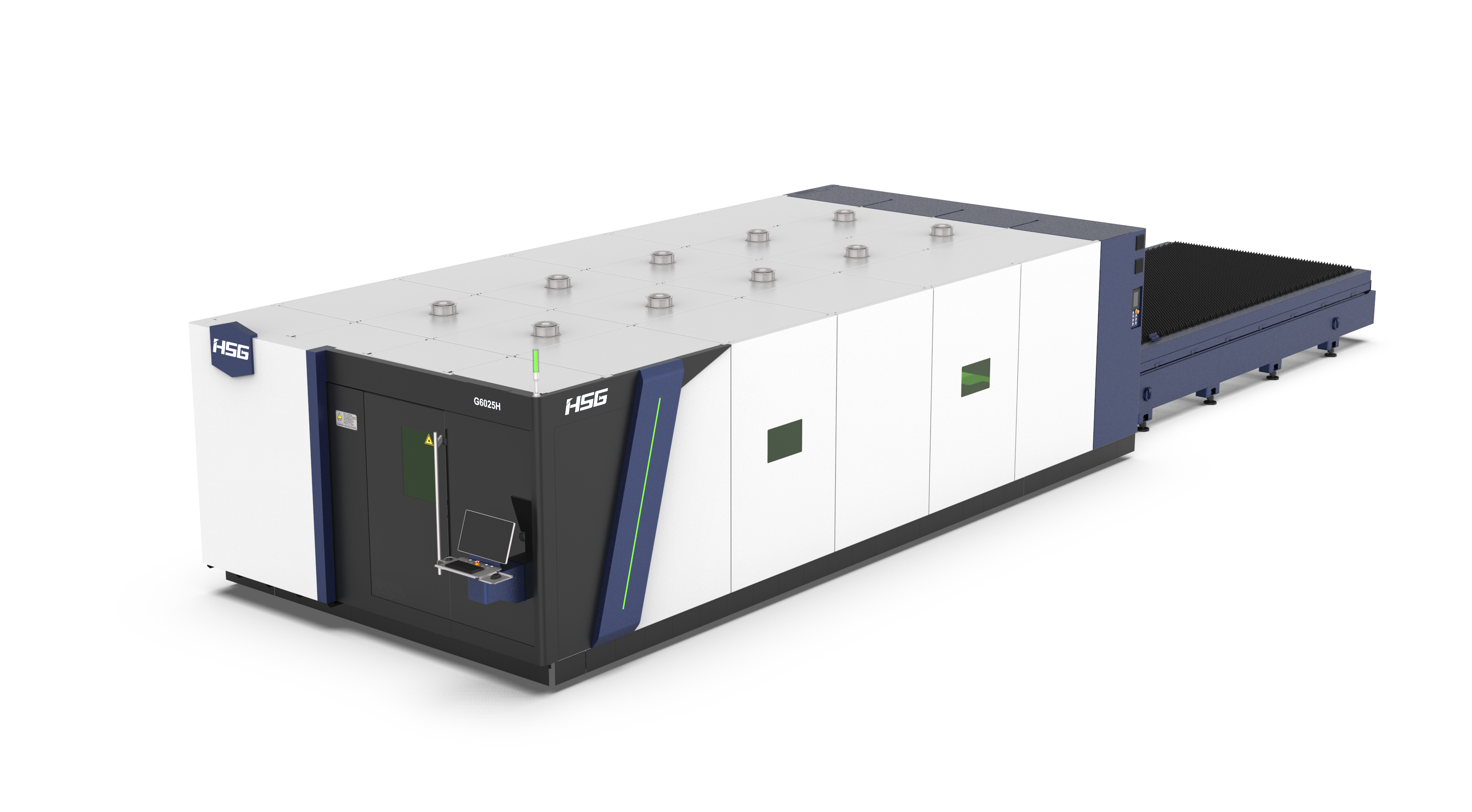

Fast efficient cutting of sheet and plate. Suitable for Carbon Steel, Stainless, Aluminium and other metals

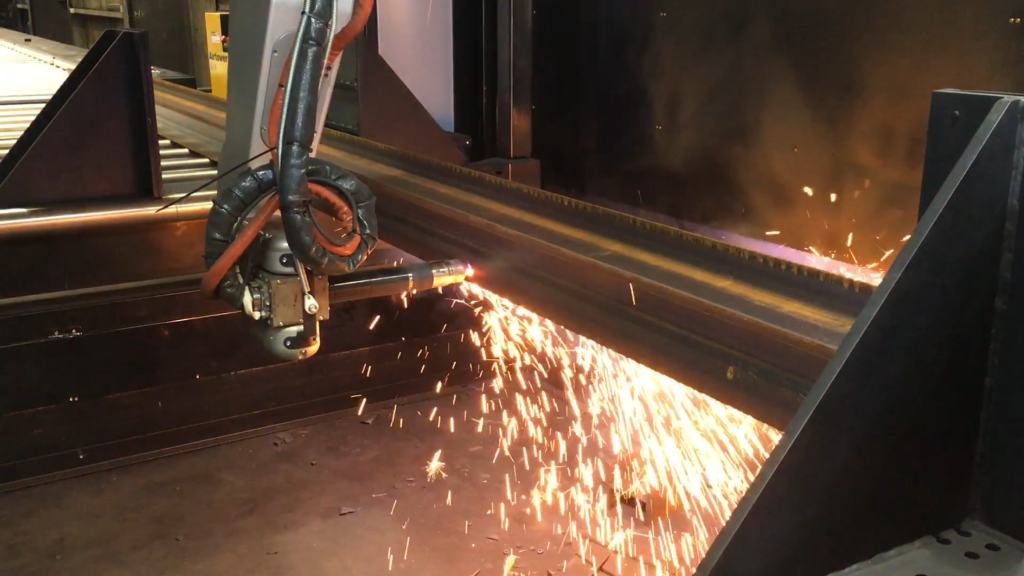

Fully automated robotic steel processing. Suitable for steel fabrication and steel construction industries

Which Machine Cuts My Material?

CLICK HERE if you 're not sure

Which Machine Suits My Industry?

CLICK HERE if you 're not sure

Which CAD/CAM Software Do I Need?

CLICK HERE if you 're not sure

ART CNC offers a full range of CNC cutting machines

ART CNC has been designing and manufacturing custom CNC machines since 1998. We are dedicated to providing the perfect fit for your business, so whatever your needs we can design or customise a machine to do exactly what you require. And because we cover the full range of cutting processes, you can be assured that we will give you unbiased information about the correct cutting process for you.

THE TRUSTED NAME IN

CNC TECHNOLOGY.

ART is one of the world’s most trusted CNC manufacturers. We proudly manufacture some of the world’s most innovative CNC Router and Plasma Profile Cutting Machines. If you are a manufacturer, you will appreciate the difference that attention to detail along with the determination to be a world leader can bring to a product. Our products can make your business more profitable by increasing productivity, reducing labour and waste while improving product quality.

Our Mission Statement…

Our mission is simple: make technology an asset for your business, not a problem.

We strive to make technology integrate seamlessly with your business so your business can grow. As your technology partner, when your business grows ours will grow with you, therefore, we will work hand in hand with you to support your growth.

We live by these words…

- Treat others the way we wish to be treated – with respect and honour.

- Tell the truth, even if it is uncomfortable.

- Keep our integrity, even if it is not convenient.

- Never berate opposition, even if they resort to lying or slander.

- Always under-promise and over-deliver.

- Deliver what the customer needs, not what we want to sell.

- We put in 100% effort on behalf of our clients.

- Provide the absolute best technical solutions within our power.

- Use our experience to guide our customers in the right way.

How We Work: Turning Challenges Into Solutions

At ART CNC, we understand that every business is unique. Your challenges, goals, and operations are unlike anyone else’s. That’s why our approach to sales isn’t about quick pitches or cookie-cutter solutions—it’s about partnership and problem-solving.

Our sales process is designed to deliver more than just a machine; it’s a journey to find the right solution that empowers your business to grow. Here’s what you can expect when you work with us:

Step 1: Listening to Understand

We begin with one simple but essential step: listening.

Your business goals, operational pain points, and vision for the future are our focus. We’ll ask questions to uncover key details:

- What challenges are you currently facing?

- How do you envision improving your processes?

- What’s your timeline and budget for achieving these improvements?

By taking the time to fully understand your needs, we can recommend solutions that align perfectly with your objectives. We don’t rush this step because it’s the foundation of everything that follows.

Step 2: Analysing Your Requirements

After our initial conversations, we delve deeper into the specifics of your operations. This could include:

- Reviewing your production workflows to pinpoint inefficiencies.

- Identifying bottlenecks in your existing processes.

- Understanding your material requirements, such as material types, sizes, and weights.

This thorough analysis allows us to assess how our machines can integrate into your business and what adjustments, if any, might be needed to ensure success.

Step 3: Presenting the Right Solutions

Once we understand your needs, we curate a selection of solutions tailored to your requirements. At ART CNC, we’re passionate about precision—not just in our machines but in our recommendations.

Here’s how we guide you through this stage:

- Machine recommendations: We highlight the specific machines, like our cutting-edge CNC plasma cutters, beamlines or CNC routers, that match your needs.

- Customised proposals: We break down how these machines will improve your operations.

- Honest discussions: If we don’t think a solution is the right fit, we’ll tell you. Our priority is finding what works best for you.

Step 4: Demonstrating the Difference

We know that seeing is believing. That’s why we offer demonstrations tailored to your unique use case.

Imagine watching one of our machines effortlessly process your parts with precise cuts and perfect finishes. These live or virtual demos show you the exact capabilities of our technology and give you the confidence to move forward.

Step 5: Transparent Collaboration

We value open and honest communication. Throughout the process, we keep you informed about every detail, including:

- Machine capabilities and potential limitations.

- Upfront costs and long-term maintenance requirements.

- Implementation timelines and necessary adjustments to your processes.

This transparency ensures there are no surprises—only solutions you feel confident investing in.

Step 6: Seamless Integration and Ongoing Support

When you decide to move forward, our work is far from over. At ART CNC, we don’t just deliver machines; we deliver success.

Here’s what you can expect after your purchase:

- Comprehensive training: We make sure your team knows how to operate the machine efficiently and effectively.

- Expert installation: Our technicians ensure seamless integration into your workflow.

- Reliable after-sales support: Whether it’s troubleshooting, maintenance, or upgrades, we’re here for the long haul.

We don’t view our relationship with you as transactional—it’s a long-term partnership designed to help your business thrive.

What Sets ART CNC Apart?

At ART CNC, we take pride in our approach because it’s built on one guiding principle: your success is our success. We don’t believe in one-size-fits-all solutions or aggressive sales tactics. Instead, we focus on building trust, solving problems, and delivering results.

Ready to Get Started?

If you’re looking for a partner who’s as invested in your success as you are, we’d love to hear from you. Contact us today to start the conversation—and let’s discover what’s possible when we work together.

Contact details.

- Australia Phone

- +61 7 3393 6555

- USA Phone

- 866-995-2937

- View our email address

- Address

- 73 Boyland Ave, Coopers Plains. QLD 4108. Australia